LINEAR POSITION DRAW WIRE TRANSDUCERS MOD. DWT

Linear position transducers have a wire rope winded on a drum, whose rotation

axis has on one side a spring to allow to wind back the rope and on the

other side a sensor that measures the drum rotation: by knowing the drum circunference and how many turns did the drum rotate, then it is

possible to precisely calculate the extracted wire rope lenght and thus

the position of the object connected to the rope.

Position measurement is absolute therefore if the machine is switched off then

it is not necessary to zero the actuators back to a repeatable known

position.Draw wire linear position transducers DWT (also

known as "wire encoders") are installed on industrial machines to

measure the positions by attaching the wire rope to the mechanical part

whose position is to be measured: the analog signal, proportional to the measured value, is then fed to the machine electronics (typically a

PLC) in order to allow a closed loop control of the machine process.

DWT transducer can be applied in a safe position far from the application

zone where only the steel rope wire reaches the position measurement is

to be done where there might be application hazards like

vibrations/electrical noise/chemicals/dirtyness that have negligible

effect on the rope.

DWT transducer wire rope is flexible

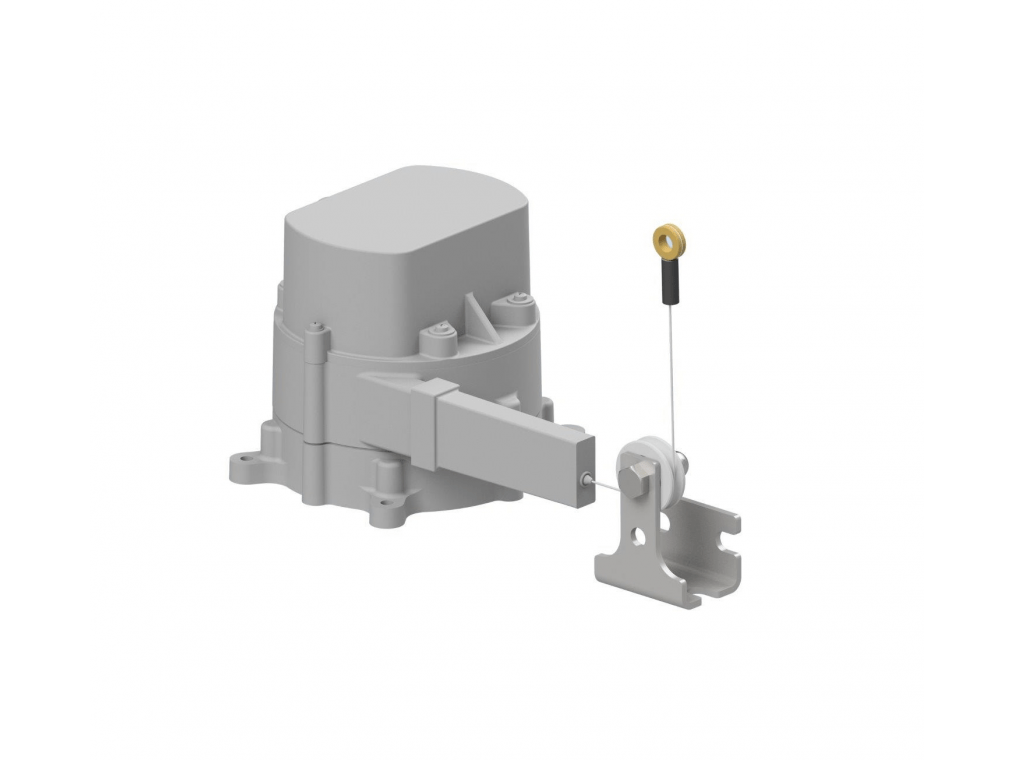

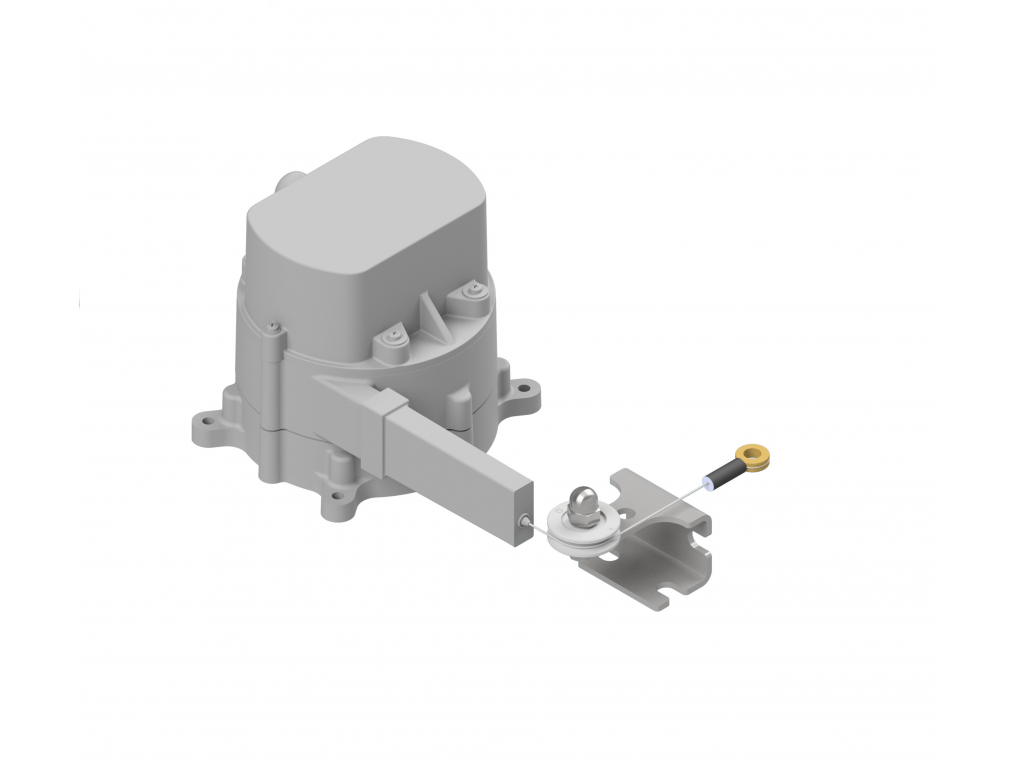

and by means of pulleys, that can be purchaed as an option, it is

possible to trace a path with several turns that allow to reach

positions difficult to reach by other means in order to do position

measurements.

DWT transducers is versatile and cost

effective because it allow to measure displacements from 1m up to 12m

with a single transducer mechanical type.

Typical

applications: automation machines, industrial vehicles, agriculture

equipment, caterpillar type vehicles, geophisical application and tests, drilling equipment, machine tools, packaging, boats etc.

TECHNICAL SPECIFICATIONS:

Full scales: 0 to 1-2,5-4-5-7,5-10-12m.

Linearity: 1-2,5-4-5mFS=±0,3% (option LN02=±0,2%),7,5-10-12mFS=±0,5%.

Outputs: 4-20mA, 0 to +10V, potentiometric 10kOhm max.

Power supply: 12 to 30Vdc (outputs 4-20mA/10V),30Vdc max (10kOhm max. potentiometric output).

Wire rope velocity: 1,5m/s max.

Rope diameter: 0,9mm.

Rope traction force: 2N/max.

Environment protection: IP65.

Materials: transducer housing= plastics+steel, rope: stainless steel and plastics.

Electrical connection: 2m cable, M12 x 8 pin male connector.

Work temperature: -40 to +85°C fixed cable, -20 a +80°C connector.

Pulley: optional pulley allows rope wire to be angled in order to easily reach the object whose position is to be measured.

Calibration certificate (not Accredia or similar): optional up to 10 points.

PRODUCT CODES:

DWT-AAA-BBB-CCC

AAA= full scale (m): 010=1m-025=2,5m, 040=4m, 050=5m 075=7,5m, 100=10m, 120=12mFS.

BBB= output signal: 10V= 0 to +10V, 420= 4-20mA, 10K=10kΩ.

CCC= electrical connection: C02= cable 2m, CN1= M12 x 8 pin straight male connector.

OPTIONS:

PU01= pulley.

CV03= external cable 3m long with M12 x 8 pin female straight connector.

CN02= external M12 x 8 pin female straight connector.

CRT= calibration certificate (not Accredia or similar) 10 points.

LN02= linearity ±0,2% (1-2,5-4-5mFS).

1-2,5-4-5-10-12mFS, linearity up to 5mFS±0,3% and ±0,5% up to 12mFS, ouputs 4-20mA/+10V/potentiometric, compact, hi environment protection, good price.